S 1950L

Video balancer - productivity and ease of use

PRODUCT DESCRIPTION

The wheel balancer for tyre shops, car dealerships and garages with medium to high tyre service volume: with touchscreen monitor and easyWeight pinpoint indicator light – An accurate, fast and easy solution to position adhesive weights on the wheel

Gold graphical user interface with touch screen functions

easyWEIGHT ™: pinpoint laser identifies exact weight placement location for increased accuracy and efficiency.

Semi-automatic input of rim diameter and offset with gauge arm

Smart Sonar ™: automatic, non-contact rim width acquisition delivers greater accuracy and ease of use for a 30% savings in complete process when compared to manual operation.

easyALU ™: touch the rim with the gauge arm to enter the rim dimensions and automatically select the weight balancing mode

Rim lighting

VPM measurement technique

Constant rotational speed

QuickBAL ™: 30% reduced cycle time, less than 4,5 seconds, maintaining the same high accuracy.

Imbalance minimisation program

Imbalance minimisation program

Split weight mode

Wheel clamped on the integrated flange by means of a quick nut

Oversize shaft

FEATURES

easyWEIGHT™

Pinpoint laser identifies exact weight placement location for increased accuracy and efficiency.

Gauge arm

Semi-automatic data entry and positioning of adhesive weights.

Gold GUI with touch screen functions

Time-saving and intuitive user interface.

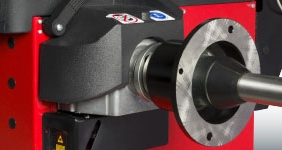

Oversize shaft

The 225 mm length allows the use of stud-hole flanges and other accessories for almost every type of rim.

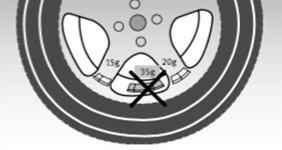

Split weight mode

Hides adhesive weights behind two adjacent spokes so they cannot be seen from the outside.

easyALU™

Touch the rim with the gauge arm to enter the rim dimensions and automatically select the weight balancing mode.

QuickBAL™

30% reduced cycle time, less than 4,5 seconds, maintaining the same high accuracy.

Smart Sonar™

Automatic, non-contact rim width acquisition delivers greater accuracy and ease of use for a 30% savings in complete process when compared to manual operation.

VPM technique

Measurement system for high precision and repeatability.

MEDIA

TECH SPECS

| Motorized | Yes |

| Wheel clamping | Quick nut |

| Diametre of shaft | 40 mm |

| Measuring speed | < 200 rpm |

| Balancing accuracy | 0.035 oz |

| Balancing accuracy | 1 g |

| Angular resolution | ± 0,35° |

| Lenght of shaft | 225 mm |

| Lenght of shaft | 8.86 inch |

| Start/Stop balance time - Check spin | 4.5 s |

| Rim diameter range | 8" - 32" |

| Offset range | 1" - 20" |

| Rim width range | 1" - 20" |

| Max. wheel diameter | 1050 mm |

| Max wheel diameter | 42 inch |

| Max. wheel weight | 70 kg |

| Max. wheel weight | 154 lbs |

| Input power (VAC) | 230 VAC 1ph 50/60 Hz |

| Dimensions LxWxH | 1313 x 868 x 1834 |

| Dimensions LxWxH | |

| Net weight | 115 kg |

Versions

The wheel balancer for tyre shops, car dealerships and garages with medium to high tyre service volume: with touchscreen monitor and easyWeight pinpoint indicator light – An accurate, fast and easy solution to position adhesive weights on the wheel

ACCESSORIES

dia. 200 mm

d.113-170mm, for balancers with 40 mm shaft,

to be used in conjunction with spacer ring #24937 only.

d. 195-214 mm, for balancers with 40 mm shaft,

to be used in conjunction with spacer ring #24937 only.

for Y2k balancers with 40 mm shaft, consisting of cone 113 -170 mm #24936 + spacer #24937

Spacer and cone 122-172 mm, for all Y2k balancers with 40 mm shaft

to be clamped with centring cones 25790 or 24936, or with a studhole flange plate

Compared to standard cones, low-taper collets have more contact area and engage the wheel at a better angle; they are also neccessary for Clad wheels because they are shorter and only contact the metal part of the wheel, but can also be used for "standard" wheels as a replacement for+E106 cones.

For light trucks MB Sprinter and VW Crafter,

series 400/ 46

pitch circle diameter 6 x 205 mm