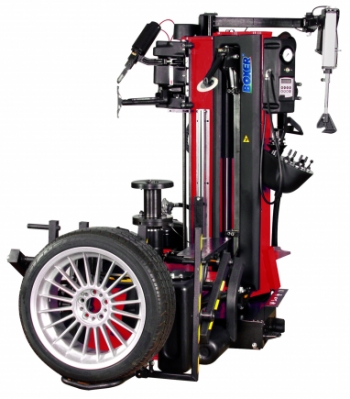

Quadriga 1000

AUTOMATION AND CONTROL

PRODUCT DESCRIPTION

Accuracy, control and power

Accurate: The automatic tyre changer Quadriga 1000 was developed to relieve the operator and to minimise error sources thanks to its substantially automatic procedures. The controlled power and accuracy of this machine allows to carry out all operations – especially bead breaking – efficiently and gently at the same time

Versatile: This tyre changer is capable of handling all conventional wheels presently in the market as well as UHP and run-flat tyres of up to 30” rim diameter and 47” wheel diameter

Ergonomic: Owing to its intelligent and ergonomic design, the time-saving procedures and its universal application the Quadriga 1000 is also suited for shops with a high tyre service volume

Fully automatic: This nearly fully automatic tyre changer offers several programs to customise mounting and demounting procedures to the individual requirements at site

Controlled: Despite of automatic operation the user is always in control of all work processes. As long as he actuates the joystick, operations are carried out automatically

Once joystick is released, the automatic procedure is interrupted – which is possible at any time, for example in order to lubricate the tyre. If necessary it is also possible to repeat program steps

FEATURES

AUTOMATIC MOUNTING DEMOUNTING CYCLE

Facilitates all mounting and demounting operations. It makes operations with run-flat tyres and UHP tyres easy.

CENTRE CLAMP

The centre-clamp design has numerous benefits: most important is the drastically reduced risk of damage and that there are no restrictions of the turntables with clamping jaws, while automatic locking of the wheel provides fast, safe and correct clamping of the wheel.

LEVERLESS TOOL

The leverless tool supersedes the conventional tyre lever. It pulls the bead over the rim edge, being as gentle to the tyre as can be and and reducing the effort of the operator.

WHEEL LIFT QUADRIGA

The ergonomic wheel lift reduces fatigue on the operator and increases productivity.

MEDIA

TECH SPECS

| M/D tool technology | |

| Tower technology | |

| Clamping System | |

| Tool vertical positioning | |

| Jaw type | |

| Rim diameter | |

| Outside clamping range | |

| Inside clamping range | |

| Max wheel width | mm |

| Max wheel width | inch |

| Max. Wheel diametre | 1200 mm |

| Wheel diameter | 47.2 inch |

| Breaking force | |

| Breaking force | |

| Rotation speed | |

| Speed control | |

| Max. torque | |

| Max. torque | |

| Bead seating- Top-side inflation | |

| Toolbox | |

| Easymont pro | |

| Wheel lift | |

| Capability | 70 kg |

| Power supply | 230 VAC 1ph 50/60 Hz |

| Power supply (Amperage) | A |

| Installed motor power | |

| Dimensions LxWxH | 1290/1350 x 2240 x 1850 |

| Dimensions LxWxH | 50.8"/53.2" x 88.2" x 72.8" |

| Net weight | 820 Kg |